Precision Machining Center

Using our accumulated know-how and wide array of personal resources, we offer a total response for all forms of machinery, covering everything from maufacturing to maintenance.

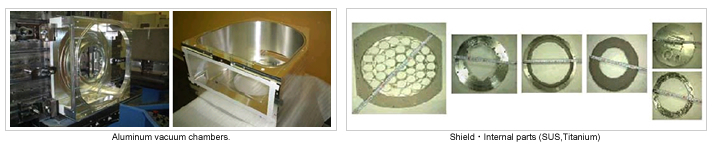

Our factory specializes in machining of stainless vacuum chambers and our services include TIG welding, and processing of aluminum vacuum chambers using state-of-the-art NC machine tools. We also specialize in carrying out various types of precision machining mainly on stainless steel and aluminum.

Since we make full use of state of the art NC machine tools, customers entrust us with various forms of precision machining

- We offer precision machining for devices that manufacture semiconductors and electronic parts, made mainly from stainless steel and aluminum

- 24-hour machining using an 18 surface palette, based on scheduled operations

- Precision processing of small-lot parts from multi-turret lathe clusters and of precision parts for medical equipment

- Machining of aluminum vacuum chambers.

- We are a factory specializing in machining of stainless vacuum chamber including TIG welding, and aluminum vacuum chamber by taking advantage of state-of-the-art NC machine tools, and also in various types of precision machining mainly on stainless and aluminum.

- Our gate-type five-sided machines, transverse machining center with an 18-sided pallet and various other types of equipment enable us to accommodate a wide range of customers' requests including high-precision metal machining and mass production machining using state-of-the-art complex NC lathes in small to large production quantities. We also utilize three-dimensional measuring instruments and other types of inspection equipment enabling us to take advantage of a complete inspection system and to maintain high quality standards.

- Gate-type five-sided machine(With universal head)

Maximum processing size:6,000×3,000×1,500

Main axis rotational speed:max;8,000rpm ATC;80

Highly rigid, state-of-the-art, high-speed, supersized machine.

This machine has the capability to process large chambers for liquid crystal devices and core chambers for semiconductor devices - Horizontal-type machining center(With 18 surface palette FMS)

Maximum processing size:1,050×800×825

Main axis rotational speed:max;15,000rpm ATC;120

Rotary index:1/1,000

Suitable for mass production machining of semiconductor process chambers.

The center utilizes an automated variation system of various types and quantities that is flexibly available for processing of stainless steel and other materials. - Complex CNC lathe (with automatic supply robot)

Maximum processing size:φ600×1,000

Main axis rotational speed:max;5,000rpm ATC;40

A state-of-the-art complex production machine for mass production precision machining of small or mid-sized diameters (20 to 600 dia)φφ

Suitable for processing semiconductor device shields and vacuum internal components (SUS, AL and titanium).